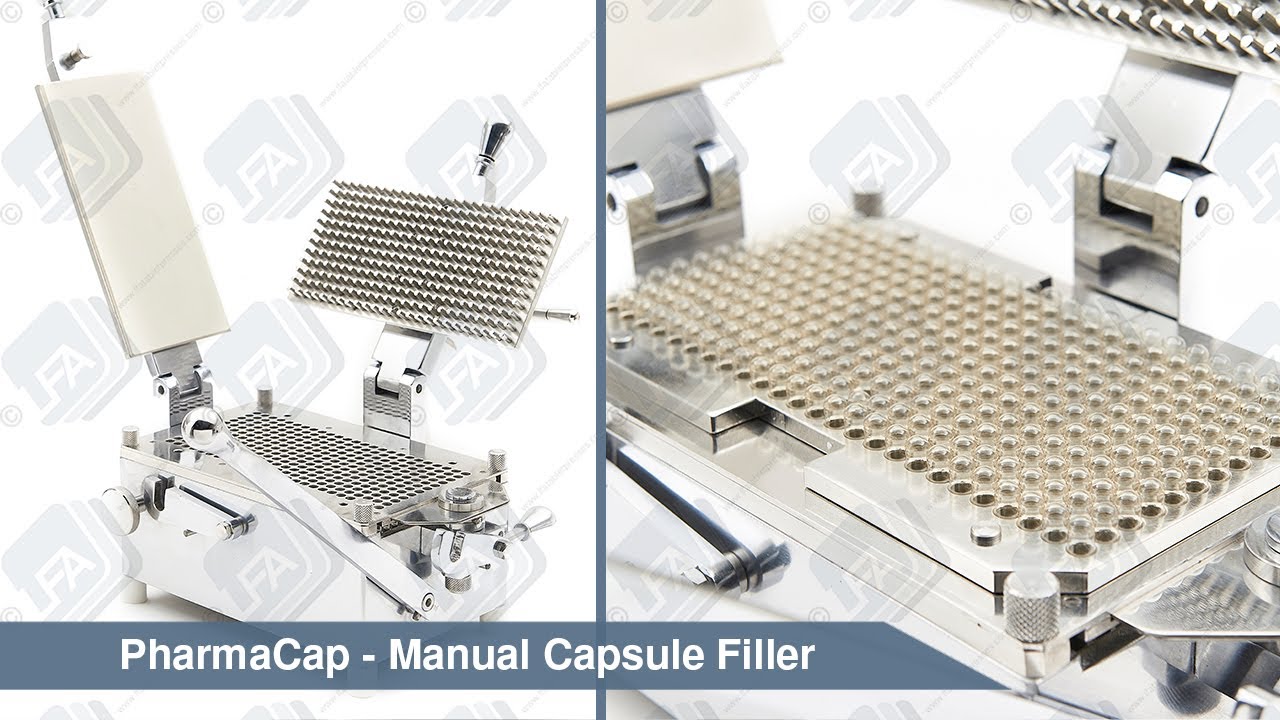

PharmaCap Capsule Filler

- Fills approximately 3,000 - 6,000 capsules per hour

- Can manufacture capsule sizes 00-5

- Constructed from 304 stainless steel

The PharmaCap from LFA Machines is the ideal solution for compounding pharmacies, Amazon sellers, and R&D departments that are looking to produce small batches of products.

The PharmaCap desktop capsule filler is one of the fastest small capsule fillers on the market. You are easily able to produce 300 capsules every with every tray. With the Automatic Capsule Loader, you can see as many as 6,000 capsules per hour. This makes it versatile and affordable.

Connect with Our Team

If you have a question or would like more details on the PharmaCap Capsule Filler, please complete the form below and someone from our team will be in touch with you soon.

Main Benefits of the PharmaCap Capsule Filler

- Compact and lightweight allowing you to store easily after use

- The cheapest way to make pharmaceutical grade capsules

- Fills approximately 3,000 capsules per hour

- Can fill up to 6,000 capsule per hour with the PharmaCap Automatic Capsule Loader

- Easy to operate and service, with no specialist skills required

- Can manufacture capsule sizes 00-5 with a simple tooling change between each of them

- Meets all GMP and cGMP requirements

- Constructed from 304 stainless steel, it is very easy to clean

- Low noise making it ideal for busy working environments

- Mechanical tamping system to ensure consistent weights

- Safe and easy to operate

- Stainless steel construction for durability and hygiene

Features

Easy to Clean

The PharmaCap from LFA is built entirely from 304 stainless steel making it easy to clean. As it is small, it can be cleaned in under 20 minutes. All of the contact parts are removable and dishwasher-safe. This means that you reduce turnaround times between products and reduce the workload at the end of the day.

Fast

The PharmaCap desktop capsule filler is one of the fastest small capsule fillers on the market. You are easily able to produce 300 capsules with every tray or up to 6000 per hour with the Automatic Capsule Loader. This makes it versatile and affordable. If you are trying to test a number of products on Amazon or produce customized batches in your Compounding Pharmacy, then this is the ideal solution.

Not only is it fast at producing capsules, but it is able to quickly change between the different capsule sizes. There are 3 base models of the PharmaCap capsule filler. The PharmaCap - L, the PharmaCap - M and the PharmaCap - S.

Models

PharmaCap - L

The PharmaCap - L is the largest of the PharmaCap range. It is able to create capsules that are sizes 00, 0, 1 and 2. This is by far the most popular model in the PharmaCap range. Size 00 and 0 capsules are the standard sized empty capsules that are used in the supplements and pharmaceutical industries. For more information on capsule sizes take a look at our size chart here.

PharmaCap - M

The PharmaCap - M is the middle model in the PharmaCap range. It is able to produce size 3 and 4 capsules. These capsule sizes are normally reserved for smaller dose products that are sub 100mg.

PharmaCap - S

PharmaCap - S is the smallest in the PharmaCap desktop capsule filler range. It is specifically designed to produce size 5 capsules. Size 5 empty capsules are normally used for very small active ingredients or for capsules that are used in applications such as inhalers.

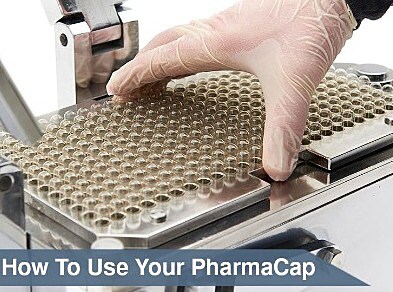

PharmaCap in Use

PharmaCap has been designed so that it is easy to use. The average operator will be able to pick up the general operation in under 30 minutes. The operation comprises of 3 main steps:

Sorting Capsules

- Place the empty capsules into the capsule holding tray and place it onto the machine

- Secure the bodies of the capsules by pulling forward the locking handle

- Lift the capsule caps off the top of the capsule body by pulling on the long leaver

- Place the tray with capsule caps to one side

- Release the locking handle to let the capsule bodies fall into the filling position

Filling the Capsules With Powder

- Place the powder guard onto the machine to make sure that the powder does not spill over

- Fill the guard with the powder to be filled into the capsules and use the spreading tool to ensure that it covers all of the capsules

- Lower the tamping tool and lock it in place

- Use the handle to compact the powder

- Unlock the tamping plate and redistribute the excess powders

- Repeat the above two steps until the capsules are full

Sealing the Capsules

- Place the tray with the capsule caps back into the PharmaCap

- Lower the cap locking plate and lock into place

- Turn the dial on the front of the machine to the right to prepare to close the capsules

- Pull the large lever down to seal the capsules shut

- Open the locking plate lock, lift the locking plate and turn the front dial to the left

- Pull down the large lever and lift the tray with filled capsules

- Turn over the capsule tray over to release all of the capsules

Get Information on

PharmaCap Capsule Filler

Enter your details to get the User manual, Spec Sheet and Video links for PharmaCap Capsule Filler

Our View

We believe that the PharmaCap is perfect for small businesses, R&D departments and Universities and Compounding Pharmacies that need to produce small batches of capsules. Its size and weight make it easy to use and store.Its 304 stainless steel construction makes it GMP (FDA) compliant and easy to clean.

In stock and ready to ship, this will often be the lowest investment with the quickest turnaround time for most businesses.

Technical Specifications

| Name | Value |

|---|---|

| Maximum Output/Hour* | 6,000 |

| Compatible Capsule Sizes | 00 / 0 / 1 / 2 / 3 / 4 / 5 |

| Filling Precision | ± 3% |

| Weight | 40kg / 88lbs |

| Length | 428mm / 16.8in |

| Height | 452mm / 17.8in |

| Width | 308mm / 12.1in |

Bores per Plate

| Plate Size | Number of Bores/Plate | Maximum Output/Hour* |

|---|---|---|

| #00 | 300 | 6,000 |

| #0 | 300 | 6,000 |

| #1 | 300 | 6,000 |

| #2 | 300 | 6,000 |

| #3 | 300 | 6,000 |

| #4 | 300 | 6,000 |

| #5 | 360 | 7,200 |